Effluent Treatment Plants (ETP) for Sustainable Industrial Waste Management

Sarvo Water’s Approach to Eco-Friendly Wastewater Solutions

As industries scale up, so do their impacts on the environment—especially through wastewater, or effluent, which is often contaminated with pollutants. Effluent Treatment Plants, or ETPs, have become essential tools for responsibly managing industrial waste. Sarvo Water combines advanced, sustainable technologies with integrating beyond-conventional treatment methods for unique ETP solutions. This blog discusses how ETP systems from Sarvo Water help in environmental protection, resource conservation, and adherence to regulations while innovating for the future of industrial waste management.

Why Effluent Treatment Matters Now More Than Ever

Industrial effluents combine harmful chemicals, heavy metals, and organic matter. If this wastewater is not treated, it might cause havoc in ecosystems, communities, and water sources. At present, due to stringent environmental regulations and demands for sustainability, industries are motivated to alter their conventional practices into more effective, cleaner ways of waste management. ETPs are an integral part of the defensive line that converts toxic effluents into clean and reusable water meeting the environmental requirements.

Sarvo Water is at the forefront of highly efficient, sustainable ETP solutions. Investment by Sarvo in advanced treatment technologies ensures industrial clients not only comply but also produce more positive results for the environment.

Sarvo Water’s Distinctive ETP Solutions

Sarvo Water’s ETPs stand out for their unique blend of cutting-edge technologies and customizability. Here are a few standout features that set Sarvo’s ETP solutions apart:

- Modular Designs for Flexibility: Sarvo’s modular ETP systems can be scaled up and adapted to suit the specific needs of different industries. This can range from a small pharmaceutical plant to large textile factories, ensuring optimal cost and space utilization.

- Energy-Efficient Processes: Sarvo’s ETPs are developed to be energy-efficient through innovative aeration and filtration technologies that reduce energy use. Lower operational costs will ensure cost-effective and sustainable waste management for industries.

- Zero Liquid Discharge (ZLD) Systems: Sarvo offers ZLD solutions to those clients with very strict environmental goals. It ensures that nothing unprocessed leaves the plant in liquid form. The technology not only removes water pollution but also can reclaim valuable resources from industries, driving a circular economy forward.

- Advanced Biological Treatment: Sarvo incorporates anaerobic and aerobic digestion technologies to treat organic contaminants effectively. These biological processes break down organic pollutants, resulting in treated water that meets or exceeds regulatory standards.

A Step-By-Step Breakdown of the Effluent Treatment Process

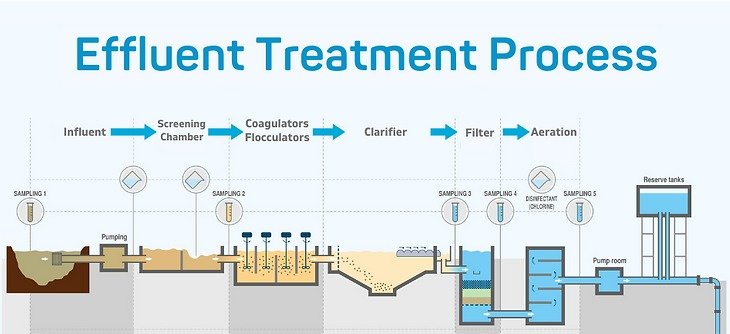

Sarvo Water’s ETPs typically follow a multi-stage process, using a combination of physical, chemical, and biological treatments to thoroughly cleanse wastewater. Here’s a look at each stage:

- Preliminary Treatment: Wastewater first undergoes screening to remove large debris and particles. Sarvo uses high-efficiency screens and grit chambers to handle high volumes, preventing system clogging and ensuring smooth operation.

- Primary Treatment: During this stage, suspended solids and oily substances are separated using sedimentation and flotation techniques. Sarvo’s Dissolved Air Flotation (DAF) systems use microbubbles to lift suspended solids and oils to the surface, where they are easily removed.

- Secondary (Biological) Treatment: Here, microorganisms play a vital role in breaking down organic matter. Sarvo’s ETPs employ both aerobic and anaerobic biological reactors, achieving high-efficiency removal of organic pollutants.

- Tertiary Treatment: The final step involves advanced filtration and disinfection to remove residual contaminants. Sarvo’s tertiary treatment solutions include ultra-filtration membranes, activated carbon filters, and UV sterilization to produce high-quality treated water suitable for reuse.

- Zero Liquid Discharge (ZLD): In ZLD systems, Sarvo incorporates evaporation and crystallization to eliminate liquid waste, producing clean water and solid waste that can be disposed of safely.

Why Choose Sarvo Water for ETP Solutions?

- Custom-Tailored Solutions: Sarvo Water understands that each industry has unique wastewater challenges. By offering tailored ETP solutions, Sarvo ensures maximum efficiency and compliance for each client.

- Eco-Friendly Innovations: With an emphasis on reducing waste, conserving water, and minimizing carbon footprints, Sarvo’s ETP systems are designed to support sustainability goals.

- End-to-End Support: From consultation and design to installation and maintenance, Sarvo Water provides comprehensive support to ensure optimal ETP performance and hassle-free operation.

- Reliable Compliance with Regulations: Sarvo Water’s ETP systems are built to meet or exceed local and international regulatory standards, giving clients confidence in their compliance.

Frequently Asked Questions (FAQs)

Q1: What types of industries benefit from ETPs?

A: Industries such as pharmaceuticals, textiles, food processing, chemicals, and metal manufacturing often require ETPs to manage wastewater containing toxic chemicals, organic matter, and heavy metals.

Q2: How does Sarvo Water’s ZLD technology work?

A: Sarvo’s ZLD technology eliminates liquid discharge by using processes like evaporation and crystallization. These processes separate water from solids, allowing the water to be reused and minimizing waste.

Q3: What is the lifespan of an ETP?

A: With regular maintenance, Sarvo Water’s ETPs can last 15–20 years or more. Sarvo offers comprehensive maintenance plans to ensure longevity and optimal performance.

Q4: How energy-efficient are Sarvo’s ETPs?

A: Sarvo Water designs its ETP systems with energy efficiency in mind, using advanced aeration and filtration technologies that reduce energy use. This helps lower operational costs while maintaining high treatment standards.

Q5: Can ETP-treated water be reused?

A: Yes, treated water from Sarvo’s ETP systems can often be reused for industrial processes, cooling, or even landscaping, depending on the level of treatment applied.

Final Thoughts

ETPs mean much more than being only compliance tools; they signify a commitment to sustainable industrial practices. Sarvo Water‘s advanced ETP solutions save industries from challenging environmental standards by conserving resources and protecting the environment. Through Sarvo Water, the industries get innovative treatment solutions tailored to meet the requirements for operation and environment. Sarvo Water ETP solutions cater to the needs of companies requiring responsible and efficient waste-water management for minimizing environmental footprint.