Water Recycling Solutions for Sustainable Industries

Introduction

- A Global Water Crisis: Discuss the increasing scarcity of fresh water and why it is time for industries to shift towards sustainability.

- Why Water Recycling is Non-Negotiable: Explain industries’ pressures—increased water costs, more stringent regulations, and environmental expectations.

- The mission of Sarvo Water: Introducing Sarvo Water‘s pledge to innovate and deliver efficient, cost-effective solutions in support of industries to manage water resources sustainably.

1. The Case for Water Recycling in Industries: Going Beyond Compliance

- Economic & Environmental Pressures: Examine how water reuse can offer dual benefits to industries by reducing their operation and conforming to environmental laws.

- Sustainable Brand Value: Explain how water recycling is not only good for the bottom line but further enhances the brand’s equity in the eyes of socially conscious consumers and partners.

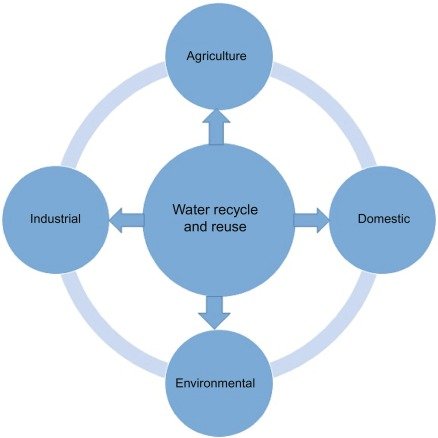

- Circular Economy Approach: How water recycling fits into a circular economy model that many industries are looking to.

2. Advanced Water Recycling Techniques and Technologies

- Membrane Bioreactors (MBRs) Explain how an MBR integrates biological treatment with membrane filtration to produce highly efficient and pure water.

- Dissolved Air Flotation (DAF): The least expensive available for high-suspended solid industries. Identify how DAF water clarification works by removing suspended materials, making the wastewater safe to reuse.

- Ultrafiltration and Reverse Osmosis Technology: Discuss the benefits offered by these technologies in ensuring that the quality of almost potable water is yielded from industrial wastewater.

- For facilities in decentralized plant locations, transport costs could be saved aside from also allowing for site recycling.

3. Sarvo Water’s Solutions for Different Industrial Needs

- Customized Solutions: How Sarvo Water adjusts water recycling systems to industry-specific needs – manufacturing, food processing, pharmaceuticals, and textiles.

- Modular Systems: Describe how Sarvo Water’s modular systems allow companies to scale their water recycling infrastructure according to production needs, thereby reducing the upfront costs.

- Water treatment, in particular, requires energy-efficient designs to reduce the recycling process’s carbon footprint.

4. Cost-Benefit Analysis: Why Water Recycling is Financially Viable

- Break down long-term savings from the investment in water recycling as reductions in water bills, lessened fees for the disposal of wastewater, and lesser fines due to violations.

- Government Incentives and Subsidies: Identify the tax breaks or subsidies offered to companies investing in sustainable water practices.

- Lower environmental impact: With reduced water extraction, transportation, and efficient recycling technologies, there is a prospect of a lower carbon footprint.

5. Case Studies: Success Stories in Water Recycling with Sarvo Water

- Case Study 1: Manufacturing Industry: In this case, a manufacturing client lowered their water costs by 40 percent with Sarvo Water’s recycling system.

- Case Study 2: Food Processing Plant: Describe how a food processing facility achieved near-zero discharge with Sarvo’s custom-designed water treatment and recycling.

- Case Study 3: Textile Factory Describe how Sarvo’s DAF system helped a textile customer manage heaver-duty waste by using closed-loop water recycling inside the production cycles.

6. The Future of Water Recycling: Innovation & Scalability

- IoT and Smart Monitoring Systems: How Sarvo Water integrates IoT to monitor and optimize water recycling processes, thereby making maintenance easy and cheaper.

- Artificial Intelligence in Water Management: AI’s Role in Predicting System Needs, Monitoring Contaminants, and Reducing Maintenance Costs.

- Scalable solutions for SMEs: Affordable, modular water recycling units available for small and medium enterprises help make sustainable practices accessible beyond the large corporation.

FAQs

-

What is the typical ROI for industrial water recycling systems?

-

-

- The ROI varies by industry and volume, but most Sarvo Water clients see cost recovery within 2-5 years due to savings on water bills and waste disposal.

-

-

How does Sarvo Water ensure the quality of recycled water?

-

-

- We use advanced filtration and disinfection methods, such as ultrafiltration and UV treatment, to ensure that the recycled water meets or exceeds industry standards.

-

-

Are there financing options for installing water recycling systems?

-

-

- Yes, Sarvo Water offers flexible financing plans, and we help clients explore government subsidies and grants to make the initial investment easier.

-

-

What maintenance is required for these systems?

-

-

- Our systems are designed for minimal maintenance, but routine checks are recommended. We offer smart monitoring services to alert you of real-time issues.

-

-

Can recycled water be used for all industrial processes?

-

- Generally, recycled water is suitable for most non-potable processes. However, we tailor solutions to meet the specific quality requirements of each application.

Conclusion

Emphasize Sarvo Water in the solution shown above about sustainable industrial practices. This will make even more industries look towards water recycling as not merely an economic opportunity but also toward the responsible resource management they are to embrace in the future.