Advanced Guide: Energy-Efficient, and DAF Plant Design

The Dissolved Air Flotation (DAF) system is a highly effective technology for high-quality water treatment in industries. Sarvo Water has introduced smart, energy-efficient, and reliable DAF plant designs, setting new standards in water treatment. These systems not only enhance the removal of pollutants but also integrate energy-efficient processes, automation, and advanced operational features.

This blog will explore how DAF systems work, their benefits, and Sarvo Water’s innovations that are leading the industry. It will also cover frequently asked questions to understand DAF technology comprehensively.

What is a DAF (Dissolved Air Flotation) System?

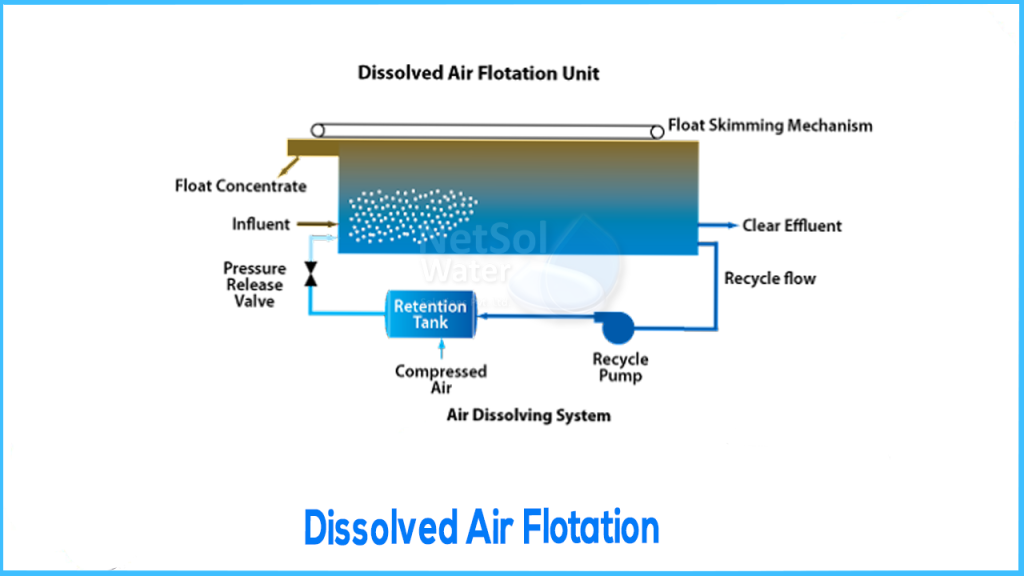

Dissolved Air Flotation (DAF) is a water treatment method that removes suspended solids, oils, greases, and other particles from water or wastewater. Air is dissolved under pressure and released at atmospheric pressure in a flotation tank or basin. Microbubbles attach to suspended particles, causing them to float to the surface.

DAF systems are highly efficient and used in various industries, including municipal wastewater treatment, food and beverage, petrochemical, and pulp and paper.

How Does a DAF System Work?

The basic operation of a DAF system can be broken down into the following steps:

- Pre-Treatment: The DAF unit often undergoes chemical pre-treatment before entering the unit, adding coagulants and flocculants to improve the aggregation of fine particles for easier removal.

- Pressurized Air Injection: Air is dissolved into the treated water under pressure in a saturation vessel. This pressurized air-water mixture is then released into the flotation chamber at atmospheric pressure.

- Bubble Formation and Flotation: As the pressurized air is released, microbubbles form. These bubbles attach to the suspended particles, oils, and grease, causing them to float to the surface.

- Skimming: The floating particles are then skimmed from the surface of the flotation tank, leaving behind clean water.

- Effluent Discharge: The treated water is collected at the bottom of the tank and can be further treated or discharged according to regulatory standards.

- Sludge Management: The collected sludge can be thickened, dewatered, or treated depending on its composition.

Sarvo Water’s Smart and Energy-Efficient DAF Plant Design

Sarvo Water’s DAF systems are designed to deliver optimal performance with minimal energy consumption, advanced automation, and a reliable operational framework. Here’s how Sarvo Water achieves excellence in DAF plant design:

1. Smart Technology Integration

Sarvo Water’s DAF systems are equipped with advanced sensors, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems for real-time monitoring and control. Automation allows operators to:

- Conduct real-time water quality analysis to determine and adjust chemical dosing accordingly.

- Optimize air injection rates for energy savings.

- Monitor system performance and detect potential issues before they cause downtime.

Example: Sarvo Water’s smart DAF plants used in large municipal wastewater treatment facilities continuously monitor incoming water quality and adjust system parameters, reducing chemical and energy consumption.

2. Energy-Efficient Design

DAF systems can consume significant amounts of energy due to the need to pressurize air and water. Sarvo Water’s energy-efficient designs focus on reducing this energy demand by:

- The treated water recaptures energy through energy recovery systems.

- They are optimizing air saturation and release mechanisms, leading to reduced air compressor usage.

- Minimizing water recirculation rates without compromising treatment efficiency.

Example: Sarvo Water’s DAF plants have achieved up to 30% energy savings in industrial wastewater treatment applications by utilizing innovative air injection techniques and optimizing flow patterns.

3. Reliability and Durability

Its DAF systems are built to last with robust materials and corrosion-resistant components by Sarvo Water. These plants are designed to operate in harsh industrial environments, maintaining their performance even in demanding conditions.

Example: In the petrochemical industry, Sarvo Water’s DAF systems are known for their long-lasting performance, even when treating aggressive, oil-laden wastewater.

Key Benefits of Sarvo Water’s DAF Plant Design

- High Pollutant Removal Efficiency: Sarvo Water’s DAF systems achieve excellent removal rates for suspended solids, oils, greases, and other pollutants. The combination of advanced chemical pre-treatment and precise air injection ensures efficient separation of contaminants.

- Reduced Operational Costs: By integrating smart technology and energy-efficient designs, Sarvo Water’s DAF plants reduce operational costs associated with energy consumption, chemical usage, and maintenance.

- Customizable and Scalable Solutions: Sarvo Water offers customizable DAF solutions tailored to meet the specific requirements of different industries and treatment capacities. These systems are scalable, making them suitable for small industrial facilities or large municipal plants.

- Environmental Compliance: Sarvo Water’s DAF systems are designed to meet stringent environmental discharge regulations. The high removal efficiency ensures that treated water can be safely discharged or reused for various applications, such as irrigation or cooling.

- Compact Footprint: DAF systems are known for their compact design, making them ideal for installations where space is limited. Sarvo Water’s design further optimizes space without compromising performance.

- Ease of Operation and Maintenance: The smart integration of automation and real-time monitoring reduces the need for manual intervention. Additionally, the use of durable materials reduces the frequency of maintenance, enhancing the plant’s overall reliability.

(FAQs) About DAF Plant Design

1. What industries benefit the most from DAF systems?

DAF systems are versatile and used across various industries. Industries that benefit most include:

- Food and Beverage: For removing oils, greases, and suspended solids from wastewater.

- Petrochemical: To treat oily wastewater and meet environmental discharge standards.

- Pulp and Paper: For the removal of suspended solids and organic matter.

- Municipal Wastewater Treatment: To enhance sewage treatment, especially when high solid removal is required.

2. How energy-efficient are Sarvo Water’s DAF systems compared to traditional models?

Sarvo Water’s DAF systems are highly energy-efficient, reducing energy consumption by up to 30% compared to traditional systems. This is achieved through optimized air injection, energy recovery mechanisms, and smart automation that adjusts system parameters based on real-time water quality data.

3. What is the typical maintenance schedule for a DAF system?

Maintenance of a DAF system typically includes regular cleaning of the flotation tank, inspection of pumps and compressors, and monitoring of air injection systems. Routine maintenance should be performed every 3-6 months to ensure optimal performance. Sarvo Water provides maintenance services and support to keep the systems running smoothly.

4. What are the sludge management options for a DAF system?

The sludge generated from a DAF system is typically high in concentration and can be managed through thickening, dewatering, or disposal. The type of sludge management depends on the industry and the nature of the contaminants. Sarvo Water offers sludge treatment solutions that complement the DAF system, ensuring efficient sludge handling and disposal.

Conclusion

Sarvo Water’s DAF plant designs are innovative, energy-efficient, and reliable. They deliver exceptional pollutant removal and minimize operational costs. These systems are suitable for municipal, industrial, and specialized applications, ensuring businesses meet environmental regulations and operate sustainably.