Exploring the Essence: Unraveling the Concepts of Industrial Reverse Osmosis (RO)

Concepts of Industrial Reverse Osmosis (RO) discover how this cutting-edge technology transforms water purification for manufacturing, offering insights into enhanced ROI and sustainable practices.

Most of today’s manufacturing companies splurges lot of money on water resources. The paramount interest of these companies is to perk up their Return On Investment (ROI). Industrial Reverse Osmosis or RO is one of the aspects that can transpire out as one of the best option in augmenting their ROI with minimal expenses.

The Process of Industrial RO

In simple terms, if we define Reverse Osmosis (RO) then it’s a high-tech method for purifying or we can say filtering the water. Osmosis is a process where various solutions or liquids that contain dissolved mineral concentrations traverse via a semi-permeable membrane. During this, the water treks through the side where the water is cleaner and moves towards the dirtier or more mineral-contaminated side of the membrane wall.

In converse to this water purification engineers have figured out ways to perform an opposite action, which can be appropriately referred as “Reverse Osmosis” or in simpler terms “RO”. In the industrial RO process, water traverses out of the high mineral concentration side to the clean side. The minerals and other contaminating agents that are dissolved in water cannot pass through the membrane and are left behind and the water that moves on the other side transpires clean and essentially mineral-free.

Practical Application of Industrial RO

The complete process of RO encompasses a colossal participation of moving parts like “Pump” and “Ultrafine Filtering Membranes,” which offer one of the most reliable and affordable ways to filter water. The real task is performed by the “Ultrafine Filtering Membranes,” which have been specially designed to filter dissolved contaminants from industrial water.

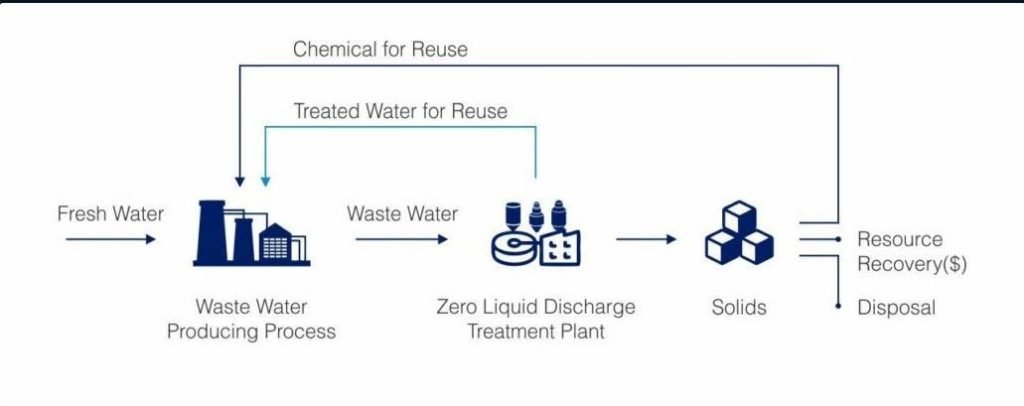

Modern RO systems are not only cost-effective; they are also incredibly powerful and reliable. This process can remove salt from seawater, for example, at astonishing rates of millions of gallons per day. RO filtration is applied prominently for the treatment of the feed water of the boiler to minimize the mineral scaling that is upshot in the efficient operation of a boiler with a lesser volume of hot water getting “blow-down” to waste. Industrial RO is frequently utilized to recover wastewater for recycling in industrial processes.

Benefits of Manufacturing Facilities

Water purification has always turned out to be complicated and costly for major companies. Reverse Osmosis when outsourced turns out to be very fruitful for these companies. Water experts can deliver a trailer-mounted RO system to the manufacturing site to help meet temporary, emergency, or long-term water treatment needs. The turnkey operation confiscates the involvement of manufacturing personnel in maintenance or any other operational tasks.

The water treatment engineers are skilled and trained in the science of filtration with the latest technologies. They are also familiar with the current industry rules and regulations that can help manufacturing businesses avoid prohibitive penalties, facility shutdowns, and other potentially catastrophic outcomes.

With the technological advances in reverse osmosis for manufacturing, this process has become both conveniently accessible and easily manageable. With the increase in expense and the relative scarcity of water, reverse osmosis filtration has a rising chart of demand.