The Industrial Reverse Osmosis RO Equipment

The Industrial Reverse Osmosis (RO) Equipment is used exclusively in the Boiler-Water pre-treatment area in the power plants. The boiler feed water quality is required to be very stringent as most of the power boilers tend to operate at elevated pressure (>700 psig [4.8MPa]). To attain this, Industrial Reverse Osmosis (RO) Equipment is followed by some type of “Demineralization” (demin) polishing equipment which is designed to reduce the solids, especially silica that is dissolved in the feed water. This shows that Industrial Reverse Osmosis is incapable by itself in providing the required boiler feed water quality to the high pressure power boilers.

On basis of the Industrial Reverse Osmosis Equipment performance (permeate water quality and quantity), the polishing demineralization equipment will be sized in the power generation facility. Hence any problem with the Reverse Osmosis Equipment Operation will have drastic effects on the demin performance. Sharp increase in costs with the increased regenerations and acid/caustic usage would transpire as the consequences of poor demin performance.

Further downstream, the impact of poor industrial Reverse Osmosis equipment performance on the power generation boilers can be severe which may ultimately lead to plant de-rating, and even boiler and turbine damage.

RO DESIGN FOR POWER GENERATION FACILITY

In order to understand the Reverse Osmosis Design for the power generation facility, four main components are to be taken into considerations. They are:

• Element

• Array(Train)

• Stage

• Pass

The industrial Reverse Osmosis Element is the building block of any RO equipment system. It is the individual component, where the RO process occurs.

There are four main designs for the elements:

• Spiral Wound – Most common design for water purification

• Hollow Fibre – Very large membrane surface areas are possible in this design. Used in seawater desalination

• Large Tube – Similar to a shell-and tube heat exchange in appearance and design. Used in special wastewater treatment and food processing applications

• Flat Plate – Similar to a plate-and frame heat exchanger. Used in food processing applications

Regardless of the element design, high pressure and flow is needed to force the pure water through the RO membrane to become permeate. Because of the need of high pressures, each element must be designed in such a way that the internal structures can withstand the feed-water pressure of several hundred psig.

The number of elements needed will be determined by the amount of the final product needed daily.

The industrial RO equipment Array is merely the way in which the elements are grouped together i.e. in series or parallel.

THE INDUSTRIAL RO STAGE

• Final water quality required

• Daily amount of water needed

• Inlet feed water quality

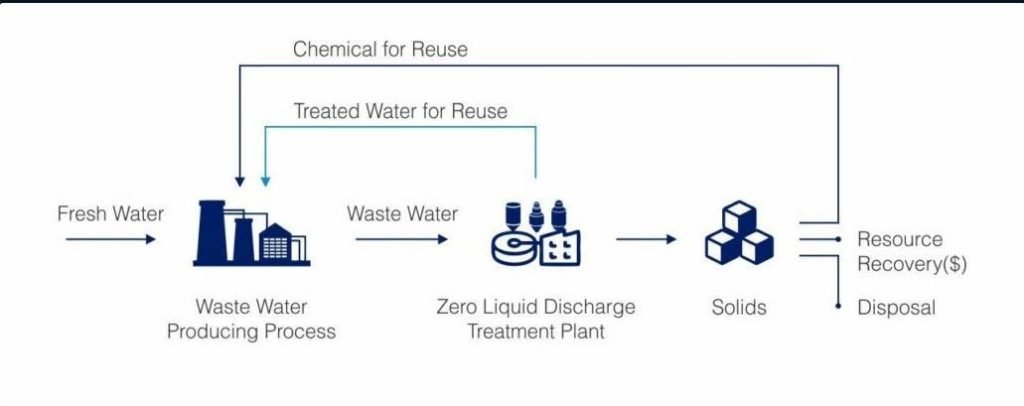

• Cost to treat wastewater

• Type of upstream feed water treatment equipment