Cost-Effective Strategies for RO-Based Wastewater Treatment

Introduction

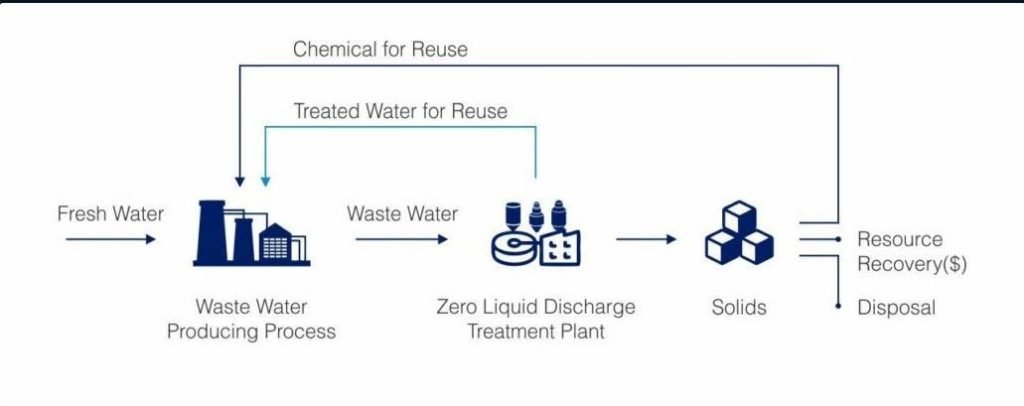

As the pressure on freshwater supplies continues to grow worldwide, industries and municipalities are experiencing negative effects. These include more frequent water supply shortages, limits on the capacity of municipal wastewater treatment plants, and escalating costs for water and effluent treatment. One of the most promising strategies for offsetting some of these impacts involves the use of advanced membrane technologies.

This paper discusses some of the technical aspects of these advances, and how membrane technologies are increasing the efficiency and reliability of industrial wastewater recycle systems while also lowering their operating costs.

Wastewater Recycle Challenges

Among the various recycling alternatives, much of membrane development over the past several years has centered on reverse osmosis (RO), which functions to separate most, if not all, substances in wastewater. RO is a more cost-effective technique for handling wastewater with high total dissolved solids (TDS) than other treatment alternatives. But one issue has caused persistent operational issues for RO systems. That issue is membrane fouling.

Extensive research has been done to determine the factors that affect membrane fouling. These factors include ionic composition, salt concentration, and the presence of organic components, and suspended solids and colloids. Various applications have been studied for the handling of ground water, surface water and sea water. But very little has been done to examine membrane fouling with the complex and constantly changing chemical mixtures in industrial wastewater flows.

Despite their critical capability to produce re-usable water, many large RO-based recycling installations have experienced difficult operational problems in the field. The most common problems include unreliable filtration production, decrease in salt rejection, the need for frequent membrane cleaning, and premature membrane failure. Each of these issues contributes to higher operating costs and lower long-term effectiveness. In some cases, the problems were significant enough to cause shutdowns at water recycle plants.

The primary cause of this performance degradation and failure is that RO membranes generally have low tolerances for a broad range of incompatible components in water. These substances, if not removed prior to the RO phase of the process, will cause scaling, fouling or permanent degradation of the RO membrane. Recognizing this problem, and to avoid its ramifications, suppliers of reverse osmosis membranes suppliers have established feed water quality criteria for RO systems. While these criteria are helpful, they do not prevent incompatible elements from finding their way into feed water flows. When they do, and feed water quality falls out of specified ranges, the industrial customer winds up owning the problem.

The ever-increasing demand for higher-quality, lower-cost industrial wastewater recycle options has paved the way for innovations with RO. One area in which newer Ultra filtration technologies are driving significant performance improvements and cost reduction is Ultra filtration (UF) pre-treatment for RO systems. Because of its versatility, robust nature and high filtrate quality, tubular microfiltration is well on the way to replacing the more traditional equipment used to remove unacceptable substances in the RO pretreatment process. These include gravity clarifiers, media filters, lime softeners and ion exchangers.

One key characteristic of Ultra filtration is that many agents that are incompatible for RO can be converted into microfiltration-compatible material and efficiently removed prior to the RO phase. Ultrafiltration and RO can work effectively in tandem, but only if the system is designed to properly support the necessary chemical reactions.

How the Ultra filtration Membrane Process Works

After the chemical reactions are completed, the pretreated wastewater is processed through ultrafiltration membrane filters that are designed to separate the incompatible precipitates from the water. The wastewater is pumped at a high velocity through membrane modules These modules are connected in a series. This creates a turbulent flow of water that moves parallel to the membranes surfaces. This pressurized, turbulent flow produces a high-shear scrubbing action which minimizes deposits of solids on the membranes’ surfaces.

During operation, clear filtrate water permeates through the membrane, while suspended solids are retained in the re-circulation loop, and then purged for further de- watering. The membranes are automatically cleaned in two ways. First, they are cleaned with chemicals when the flux drops to below the specified design level. Second, these systems have automatic back-pulse mechanisms that provide physical surface cleaning by periodically reversing the direction of the filtrate flow. These automated cleaning functions are key components in the design of these systems and critically important to their reliability and long-term performance.

Reverse Osmosis Process

Pre-treated wastewater in these systems is typically pressured between 200 to 600 psig and processed through thin-film composite or cellulose acetate RO membranes. The feed stream is separated into permeate (clean water) usually 75 to 80 % of the feed (recovery), and concentrated brine containing the separated salts (reject). The permeate water generated by these systems is cleaner and less conductive than that of most municipal water supplies. That said, the nature of customers’ specific wastewater requirements, and their objectives for recycling and reuse, must be the primary factors that drive the system design, chemical reactions, and membrane configurations for their RO systems.

Ultra filtration – RO Installations

A large number of installations have successfully combined proper chemical reaction with Process and Water’s high-flux, tubular microfiltration and RO systems for recycling of wastewater from various industries. Following are examples of selected installations.

• Textile – A major Textile Industry Unicotsyn Pvt Ltd Balotara Rajasthan operates a 10m3/hr UF/RO system for reusing of wastewater.

• Food – A Corn Chips manufactures in Roorkee(Uttar Pradesh) operates a 7.5m3/hr UF/RO system for recycle wastewater.

Conclusion

Ultra filtration, when coupled with an appropriate chemical pretreatment can provide a cost-effective, high-performance method for pretreatment of industrial wastewater RO systems. Compared to conventional wastewater treatment operations, UF systems have smaller footprints and lower operating costs. In addition, high quality and consistent filtrate produced by modern UF systems leads to improved overall performance of the RO system. As has been proven true in the field, a well-protected RO membrane can be operated effectively for several years before replacement is required.

Against the backdrop of today’s global water supply issues, companies across all industry segments are realize that it makes good business sense to become more self-sufficient through the recycling of the water resources they use to support their production processes. Whatever the industry or the specific requirement, Process and Water is ready to help customers meet their production water challenges with UF-RO systems that are among the most innovative in the industry.