Operational Parameters for Choosing the Right RO System in Power Generation

Delve into the crucial factors for choosing the right RO system in power generation. Uncover the secrets to maximizing efficiency, ensuring your system performs at its best for the long haul. Make wise decisions for your facility’s water treatment requirements with insights that matter

Considering the power generation facility, the final end product is electricity that is produced from the energy supplied by steam to the system. Hence forth we can say that an uninterrupted steam production is vital for attaining this. This directly relays to the significance of the feed-water quality for the boilers. Over the last 15 years, the use of RO in power generation facilities has become increasingly common with the newly built facilities.

Yet Reverse Osmosis retrofits very easily to the boiler-water pre-treatment systems of large and old power generation facilities, irrespective of the fuel source. This article presents 5 operational parameters for your consideration prior to purchasing a RO system for your Power Generation facility.

Industrial Reverse Osmosis Parameter

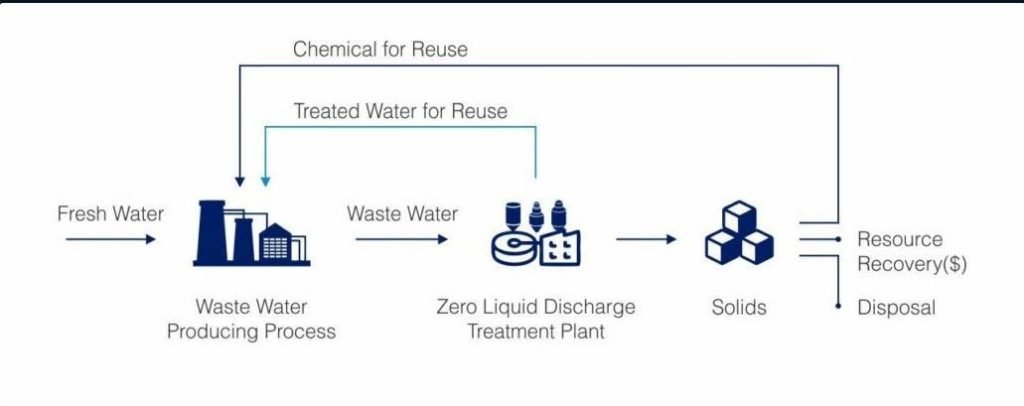

#1: The Cost of Wastewater Treatment Wastewater treatment or disposal costs are continually increasing. For those plants where the cost is becoming punitive, it might make more economic sense to design the wastewater RO system with additional stages to reduce wastewater to the minimum possible amount. In some “zero discharge” power generation facilities, specialized Reverse Osmosis systems and other equipment such as crystallizers may be required.

To provide an example of just how dramatically multi-staging can reduce wastewater volume, consider that a 400 gpm, 400 micromho stream can be reduced to just 7.5 gpm with a 3-Stage system. The conductance of course increases dramatically along the way rising from 400 micromho to 21,320 micromho! Industrial Reverse Osmosis Parameter

#2: Choose Either Cellulose Acetate (CA) or Polyamide Composite (PA) RO Membranes Cellulose Acetate and Polyamide Composite membranes vary widely in the way of their physical and chemical resistance. Fluid temperature, pH and chlorine resistance are just 3 examples of fluid characteristics that would make you favour one over the other. Operating pressure is another considerable factor. CA membranes can operate at significantly higher pressures (greater than 450psi) vs. PA membranes (300psi maximum).

Chlorine residual content, common in most municipal water system streams, can be tolerated just fine by CA membranes but if PA membranes are used then they must be neutralized by chemical means or be removed by activated carbon filtration. A complete detailed comparison of CA and PA membrane types is contained within the white paper referenced below.

Anticipate the Maintenance Requirements of the RO System Fouling of RO membranes will occur. Prevention is by far the best way of approaching this issue. Pre-treating the RO feed water for common foulants will reduce the maintenance burden and will ensure longer RO runs between cleaning or membrane replacement. Industrial Reverse Osmosis Parameter

#3: Prevent scaling of the RO membranes by hardness, strontium, or barium.

The three most common means of preventing scale that builds up in Power Generation RO systems are;

• Feeding acid to control pH,

• Installing a softener ahead of the RO system and

• Feeding an anti-scalant.

#4: Prevent microbiological fouling of the membrane.Generally microbiological fouling does not cause as much damage as mineral scale does, but it can significantly reduce the efficiency of a Reverse Osmosis system. Again, preventing fouling is a far more effective strategy than fouling remediation. Deterrence of Microbiological fouling of Reverse Osmosis systems is generally done by controlling the MB content in the RO feed water to a specified maximum extent using a biocide.

#5: Prevent non-microbiological organic fouling of the RO membrane. This is the most successfully done by controlling the COD of the RO feed water. If the RO feed water is a plant service water and uncontaminated (or does not contain recycled water or waste water) then the COD is always a colour or decaying vegetation. Both can be removed through proper upstream clarification or an anion exchanger. If the RO feed water contains a recycled or waste component, then the COD can be almost anything. In this case, proper upstream treatment using secondary (biological) treatment of the waste or recycled stream will be needed to reduce the COD to levels such that non-biological organic fouling of RO membranes does not occur.