Understanding Zero Liquid Discharge Solutions with MVR

In an era where environmental sustainability and efficient resource management are paramount, industries are increasingly adopting advanced technologies to minimize waste and optimize water usage. One such cutting-edge approach is Zero Liquid Discharge (ZLD) solutions, particularly those utilizing Mechanical Vapor Recompression (MVR) technology. This blog explores what ZLD with MVR entails, its benefits, challenges, and frequently asked questions to provide a clear understanding of this innovative solution.

Image Sourse by Freepick

Image Sourse by Freepick

What is Zero Liquid Discharge (ZLD)?

Zero Liquid Discharge is an environmental management strategy to eliminate liquid waste discharge from industrial processes. The goal of ZLD is to treat all wastewater generated in a way that allows for the recovery and reuse of water, leaving behind minimal or no liquid waste. This approach helps industries comply with stringent environmental regulations and conserve valuable water resources.

What is Mechanical Vapor Recompression (MVR)?

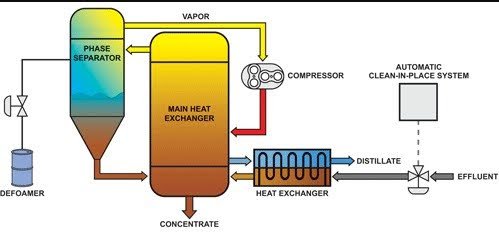

Mechanical Vapor Recompression is a thermal process used in various applications, including desalination, wastewater treatment, and concentration of solutions. MVR works by compressing vapor generated from a liquid solution, which increases its temperature and pressure. This compressed vapor is then used as a heat source to evaporate additional liquid, reducing the need for external energy inputs. In essence, MVR enhances the efficiency of the evaporation process by recycling the energy within the system.

How Does MVR Fit into Zero Liquid Discharge Solutions?

When integrated into a Zero Liquid Discharge system, MVR significantly improves the efficiency of water recovery and waste management. Here’s how:

- Efficient Energy Use: MVR systems use less energy compared to traditional evaporation methods; consequently, they recycle heat within the system. Moreover, this efficiency is crucial for ZLD applications, where the goal is to minimize energy consumption while, at the same time, maximizing water recovery

- Reduced Operational Costs: By lowering the energy requirements, MVR systems help reduce operational costs, making ZLD solutions more economically viable for industries.

- Enhanced Water Recovery: MVR technology facilitates the evaporation and condensation of water, allowing for the recovery of high-quality water that can be reused in industrial processes.

- Minimized Waste: The remaining concentrated brine or waste is often easier to handle and dispose of, as it is a smaller volume compared to the original wastewater.

Benefits of ZLD Solutions with MVR

- Environmental Compliance: ZLD with MVR helps industries meet strict environmental regulations by eliminating liquid waste discharge and reducing pollutants.

- Water Conservation: By recovering and reusing water, industries can significantly reduce their reliance on external water sources; consequently, this contributes to overall water conservation efforts.

- Cost Efficiency: Although the initial investment in ZLD systems with MVR can be high, the long-term savings in operational costs and water procurement can offset these costs.

- Reduced Footprint: MVR technology reduces the need for large evaporation ponds or additional treatment facilities, minimizing the physical and environmental footprint of industrial operations.

Challenges of ZLD Solutions with MVR

- High Initial Costs: The establishment of ZLD frameworks with MVR can be costly, including noteworthy capital ventures for hardware and innovation.

- Complexity: MVR systems are intricate and necessitate the expertise of skilled personnel for their operation and maintenance.

- Energy Consumption: While MVR systems are energy-efficient compared to traditional methods, they still require a substantial amount of energy, which can be a challenge in regions with high energy costs.

- Scaling Issues: The concentration of salts and other impurities in the wastewater can lead to scaling and fouling in MVR systems, requiring regular maintenance and cleaning.

FAQ Regarding MVR-Based Zero Liquid Discharge Solutions

Q1: What industries can benefit from ZLD solutions with MVR?

A1: ZLD solutions with MVR are beneficial for industries with significant wastewater production, such as the chemical, pharmaceutical, textiles, and food and beverage industries. These industries often face stringent regulations and high water usage, making ZLD with MVR a viable option for sustainable water management.

Image Sourse by Freepick

Q2: How does MVR technology compare to other evaporation technologies?

A2: MVR technology is more energy-efficient than traditional evaporation methods because it recycles the heat generated during the evaporation process. This leads to reduced operational costs and reduced energy consumption. Compared to other methods like multi-effect distillation (MED) or multiple-effect evaporators, MVR systems are often more compact and have a higher heat transfer efficiency.

Q3: What types of wastewater can be treated using ZLD with MVR?

A3: ZLD with MVR can treat various types of wastewater, including high-salinity brines, industrial process waters, and effluents containing organic and inorganic contaminants. The technology is versatile and can be adapted to different types of wastewater depending on the specific needs of the industry.

Q4: What are the maintenance requirements for MVR systems?

A4: MVR systems require regular maintenance to ensure optimal performance. This includes monitoring and cleaning components to prevent scaling and fouling, checking for leaks, and ensuring the system operates within specified parameters. Maintaining the equipment’s efficiency and extending its lifespan require routine maintenance.

Q5: Can ZLD frameworks with MVR be coordinated with existing wastewater treatment offices?

A5: ZLD frameworks with MVR can be coordinated with existing wastewater treatment facilities. This integration involves retrofitting the existing system to accommodate the MVR technology and optimize the overall treatment process. Integration can help improve the efficiency of water recovery and reduce the environmental impact of the facility.

Q6: What is the typical payback period for investing in a ZLD system with MVR?

A6: The payback period for a ZLD system with MVR varies depending on factors such as the size of the system, the volume of wastewater treated, and local energy costs. The payback period typically spans from 3 to 7 years. Industries with high water and energy costs may experience a shorter payback period due to the significant savings in operational costs.

Conclusion

Zero Liquid Discharge solutions with Mechanical Vapor Recompression represent a significant advancement in industrial wastewater management. By efficiently recovering water and minimizing waste, this technology supports environmental sustainability and resource conservation. The long-term advantages of cost savings, regulatory compliance, and decreased environmental impact make MVR systems a worthwhile consideration, despite their initial investment and complexity for many industries. As technology continues to evolve, ZLD with MVR is likely to become an even more integral part of sustainable industrial practices.