Revolutionizing Water Recycling: Zero Liquid Discharge Systems with Sarvo Water

In an era where water scarcity and environmental sustainability are pressing global issues, industries must adopt advanced practices to minimize their ecological footprint. At Sarvo Water, we are dedicated to leading the charge in water recycling through innovative Zero Liquid Discharge (ZLD) systems. Our ZLD solutions are transforming how industries manage wastewater, ensuring that every drop of water is recycled and reused, thus supporting a sustainable future.

Understanding Zero Liquid Discharge (ZLD)

A state-of-the-art method for treating water called Zero Liquid Discharge seeks to completely eradicate liquid waste. Instead of discharging wastewater into the environment, ZLD systems treat and recycle all wastewater, leaving only solid waste for disposal. This holistic approach ensures that water is conserved and contaminants are managed effectively, aligning with stringent environmental regulations and promoting sustainability.

The Imperative for ZLD in Water Recycling

Water recycling has become essential due to several compelling factors:

- Environmental Impact: Traditional wastewater treatment methods often result in the discharge of treated effluent into natural water bodies, which can lead to pollution. ZLD systems prevent this by ensuring that all water is either recycled or evaporated, safeguarding ecosystems and water resources.

- Regulatory Compliance: With increasing regulations on wastewater management and water use, ZLD systems help industries meet compliance requirements, avoiding fines and operational disruptions. This is particularly crucial in industries with high water usage and stringent discharge limits.

- Resource Efficiency: Water is a finite resource, and recycling wastewater through ZLD systems conserves it by reducing the need for fresh water intake. This not only supports sustainable water management but also enhances the resilience of industries in water-scarce regions.

- Cost Savings: Although the initial investment in ZLD technology can be significant, the long-term savings on waste disposal and water procurement can be substantial. Additionally, recovered by-products from wastewater can provide additional economic benefits.

How ZLD Systems Enhance Water Recycling

Source of image Freepik

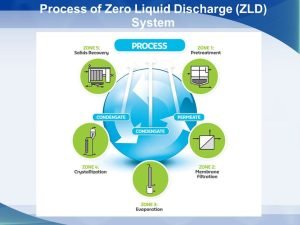

Sarvo Water’s ZLD systems employ a comprehensive approach to ensure maximum efficiency and effectiveness in water recycling. Here’s a step-by-step look at how our systems work:

- Collection and Pre-treatment: The process begins with the collection of wastewater from various industrial processes. This water undergoes pre-treatment to remove large particles, oils, and greases through filtration and separation. Pre-treatment is crucial for protecting downstream equipment and ensuring efficient processing.

- Chemical Treatment: Following pre-treatment, the water is subjected to chemical processes such as coagulation, flocculation, and neutralization. These processes help in removing dissolved contaminants and preparing the water for advanced treatment stages.

- Biological Treatment: To address organic pollutants, we utilize biological treatment methods like activated sludge or membrane bioreactors (MBRs). These technologies use microorganisms to break down organic matter, effectively purifying the water.

- Advanced Treatment: Our ZLD systems incorporate advanced technologies such as Reverse Osmosis (RO), Nanofiltration (NF), and Electrodialysis. These methods are essential for removing any remaining contaminants, producing high-quality water that can be reused within the industrial process or for other applications.

- Concentration and Evaporation: The concentrated brine or residual sludge from advanced treatment is processed through evaporation or crystallization. This step involves thermal processes to recover water and convert the remaining material into solid waste.

- Solid Waste Management: The solid waste generated, often consisting of salts or other residues, is managed through appropriate disposal methods. Depending on the material, this could involve landfilling or further processing to extract valuable by-products.

- Water Reuse:The cleaned water is either recycled back into the manufacturing process or put to different uses, including cooling or irrigation.This completes the loop, ensuring that no liquid waste is discharged and all water is utilized efficiently.

Benefits of Sarvo Water’s ZLD Solutions

Sarvo Water’s ZLD systems offer a range of benefits that enhance water recycling and support sustainability:

- Tailored Solutions: We design ZLD systems to meet the specific needs of each industry, ensuring optimal performance and efficiency. Our solutions are customized to address unique wastewater characteristics and recycling requirements.

- State-of-the-Art Technology: Our systems incorporate the latest advancements in water treatment and recycling technologies, providing reliable and effective solutions for even the most challenging wastewater scenarios.

- Sustainability Commitment: By implementing ZLD systems, we help our clients achieve their sustainability goals, reducing their environmental impact and promoting responsible water management practices.

- Expert Guidance: Our team of experts offers comprehensive support throughout the lifecycle of the ZLD system, from design and installation to maintenance and troubleshooting. We ensure that our systems operate smoothly and efficiently.

- Economic Advantages: While the initial investment in ZLD technology can be high, the long-term benefits include reduced waste disposal costs, water savings, and potential revenue from recovered by-products. This makes ZLD a cost-effective solution in the long run.

Addressing Challenges in ZLD Systems

Despite the numerous advantages, there are some challenges associated with ZLD systems:

- Initial Capital Investment: The cost of implementing a ZLD system can be substantial. Nonetheless, the investment is frequently justified by the long-term savings and benefits.

- Operational Complexity: ZLD systems involve complex technologies and require skilled operators for effective management. Proper training and maintenance are essential for optimal performance.

- Energy Consumption: Some ZLD processes, particularly evaporation, can be energy-intensive. It’s important to consider energy efficiency and explore renewable energy options to minimize the environmental impact.

Looking Ahead: The Future of ZLD and Water Recycling

The future of Zero Liquid Discharge and water recycling is promising, with ongoing advancements in technology and increasing adoption across various industries. At Sarvo Water, we are committed to staying at the forefront of these developments, continuously enhancing our ZLD systems to deliver even greater efficiency and sustainability.

In conclusion, Zero Liquid Discharge systems represent a revolutionary approach to water recycling, offering significant environmental and economic benefits. By choosing Sarvo Water’s ZLD solutions, industries can achieve regulatory compliance, conserve valuable resources, and contribute to a more sustainable future. Get in touch with us right now to find out more about how our ZLD systems can improve your water management procedures.