Types of Evaporators and Their Applications in Wastewater Treatment

Discover the importance of evaporators in wastewater treatment. Learn about types and applications of effective water conservation.

Evaporators And Its Types

More and more Applications are considering evaporation as an alternative method for wastewater treatment. With its help, it is possible to concentrate or eliminate salts, heavy metals, and other hazardous substances from the solution.

It can also concentrate liquid wastes before further treatment and disposal or extract valuable byproducts from a solution.

When water conservation is a top concern, most applications of the technology also yield high-quality, reusable distillate, which is a critical component.

Evaporator Systems Types:

Falling Film Evaporators

The heat exchanger is a falling film evaporator. Thus, it comprises a tube heat exchanger and a vertical shell. As a result, a thin film of concentrated liquid is deposited on the top of the tube and flows towards the surface tube.

As it strengthens, it produces vapor, which improves heat transfer and separates the vapor and liquid.

A solution is concentrated during evaporation when part of the solvent – usually water – evaporates and leaves behind a salty liquor that consists almost entirely of solutes, or soluble solids, from the initial feed.

The process can be accomplished automatically in solar evaporation ponds or with commercially sold evaporation equipment.

Expense, availability, and potential odor issues are typically barriers to solar evaporation ponds, while mechanical evaporators are more portable, reliable, and efficient.

LTV (Long Tube Vertical) and Rising Film Evaporators

Falling film evaporators and rising film evaporators are extremely similar. Simply put, it’s the opposite of the film Falling.

A vertical shell and tube heat exchanger is a heat exchange device consisting of a vertical shell and a tube heat exchanger.

The bottom part of the tube is where the concentrated liquid is poured. Thus, when the temperature increases, the vapor is produced and the liquid rises, causing the two to separate.

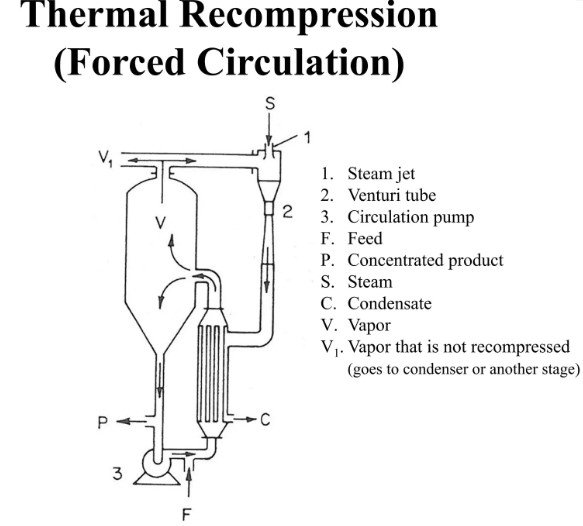

Forced Circulation Evaporators

A combination can be separated using forced circulation evaporators, which cannot be achieved with a standard evaporation unit.

Therefore, the forced spherical evaporator increases the velocity of liquid flow from 0.3 to 1m/s in the normal spherical evaporator to 2 to 6m/s.

Therefore, it has a circulation pump, making it suitable for both heat exchanger and flash separation.

Therefore, it separates the mixture without using the usual conventional boiling. Therefore, it consists of a heat exchanger tube with a vertical cover and a centrifugal pump.

Plate Evaporators

Plain evaporators are mostly used in the food and beverage industries. These consist of a plate and frame heat exchanger.

A thin liquid film moves between the plates in a plate evaporator to facilitate evaporation. Therefore this type of evaporator is often used to process milk, coffee, fruit purees, syrups, and juices.

Thermal Vapor Recompression(TVR)

By acting as a thermal compressor, a thermal vapor recompression evaporator reduces the amount of steam required for evaporation.

Therefore, the vapor stream is compressed to a higher pressure and temperature by a steam jet pump.

Mechanical Vapor Recompression (MVR)

Compressing water vapor results in an increase in temperature and pressure during mechanical vapor recompression.

Thus, the temperature difference between liquid and vapor causes an increase in temperature. Additionally, additional heat transfer is produced by the heat exchanger. To generate more steam, the compressed steam is sent back again.

As a result, the process is both energy-efficient and energy-recoverable.

Conclusion

evaporators play a crucial role in wastewater treatment, offering a sustainable and effective solution for concentrating or removing contaminants from water.

The different types of evaporators, such as falling film, rising film, forced circulation, plate, and thermal vapor recompression, provide various options for different applications and industries.

Evaporators not only help in waste minimization but also resource recovery, as they can extract valuable byproducts from the solution. Additionally, their ability to produce high-quality distillate makes them ideal for water conservation efforts.

With ongoing technological advancements, evaporators continue to evolve, offering more efficient and environmentally friendly solutions for wastewater treatment challenges.

As industries and communities strive for sustainable practices, the role of evaporators in wastewater treatment will only become more significant in the future.